Agitator For Chemical Process Plants

Introducing our range of high-quality Agitators for Chemical Process Plants, designed and manufactured to meet the demanding requirements of the chemical industry. Our agitators are designed for a wide range of applications, from mixing and blending to homogenization and dispersion.

Our agitators are made from high-quality materials such as stainless steel, carbon steel, and other corrosion-resistant alloys, ensuring maximum durability and reliability even in harsh environments. We offer a variety of agitator types including top entry, side entry, and bottom entry, each designed to provide optimal mixing and blending performance for specific applications.

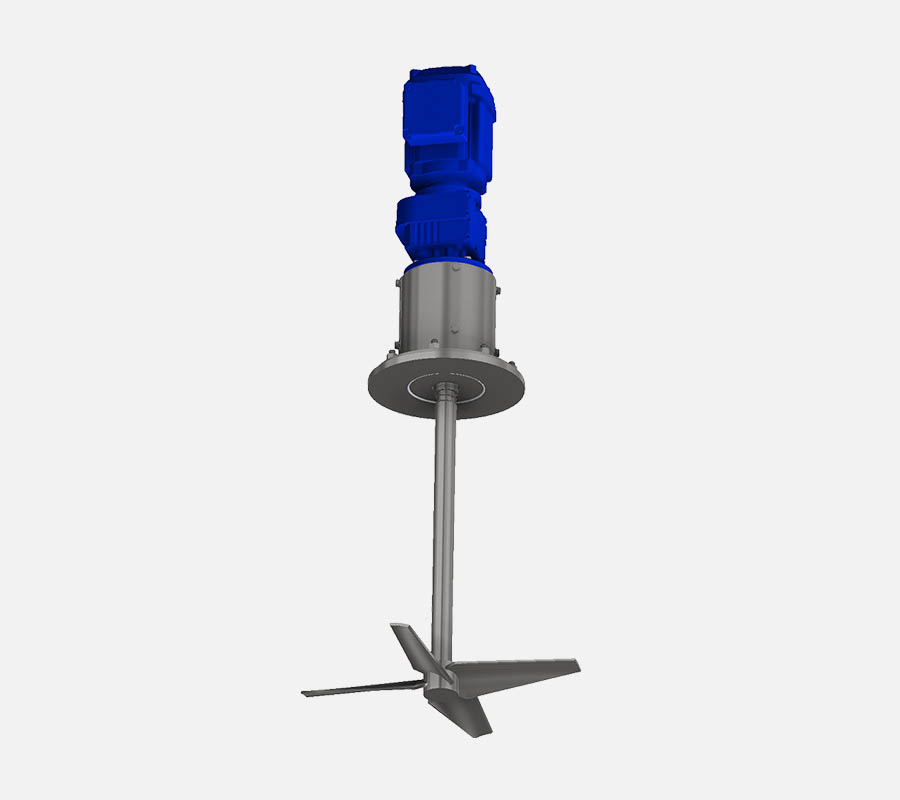

Top Entry Agitators

Designed for applications that require high flow rates and high levels of mixing intensity. Our top entry agitators are equipped with advanced impeller designs that provide superior mixing performance while reducing energy consumption.

Side Entry Agitators

Ideal for applications that require mixing of large volumes of liquids with solids. Our side entry agitators are designed to provide effective mixing and blending while minimizing the risk of agglomerates or settling.

Bottom Entry Agitators

Suitable for applications that require high-speed mixing and dispersion of liquids and solids. Our bottom entry agitators are equipped with advanced impeller designs that provide superior mixing performance while reducing energy consumption.

We offer customized agitator solutions to meet the specific requirements of our clients. Our team of experts works closely with our clients to understand their specific needs and design agitators that provide optimal performance and efficiency.

Our agitators are backed by comprehensive after-sales support, including installation, maintenance, and repair services. We also provide training and technical support to help our clients optimize the performance of their agitators.

Contact us today to learn more about our range of agitators for chemical process plants and how we can help you improve your process efficiency and productivity.

Material of Construction :

We offer a wide range of dosing systems that cater to different applications and industries. Our product range includes:

- Lantern: Carbon steel / CI / AISI 316 / AISI 304

- Bearing Housing: Mild steel / CI / AISI 316 / AISI 304

- Coupling: Mild steel / AISI 316 / AISI 304

- Shaft: Carbon steel / AISI 316 / AISI 316L / AISI 304 / Rubber lining, Fiber reinforced plastic (FRP) lining, Glass lining also available as per clients need. (We also provide the agitator with special grade material based on clients need)

Feature :

- Robust Design & Construction.

- Sturdy Lantern & Bearing Housing Design.

- Shaft Diameter range 20 mm to 250 mm.

- Viscosity handle up to 200 Ns/m2

- Wide range of Impellers.

- Mechanical seal (accordance to API 682)/Stuffing box facility in Lantern.

- Bottom Support arrangement (If required).

- Noise Less operation.

- Less Vibration.

- Less as well as Easy Maintenance.